FlowMotion’s Check Valves are available in sizes up to 2″ in Carbon Steel (Zinc Dichromate plated for added corrosion resistance), 304/316 Stainless Steel, Brass, and Aluminum. Available elastomers include Buna N, EPDM, Viton, Silicon, and Teflon. Valve internal components can be customized to fit your exact application requirements.

Our Full Port, Non Return Valves provide more flow and lower pressure drops than conventional check valves. Our elastomer hinge check valve design takes performance to an entirely new level by eliminating the restrictive valve seat and substantially increasing the valve’s open area and flow coefficient (Cv). They are ideal for application in vacuum pumps, compressed air, and gas systems as well as in water systems where low head loss and elimination of water hammers are desirable.

Ball Seat Type

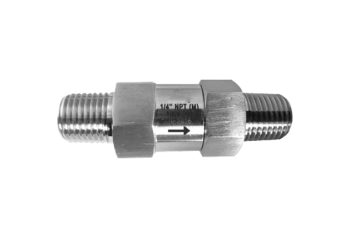

Spring Loaded Type (M X M)

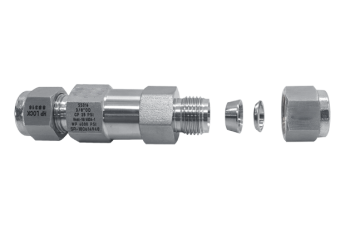

High Pressure – Spring Load Type

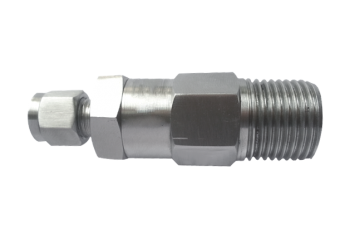

Spring Loaded Type (OD X M)

Piston Type

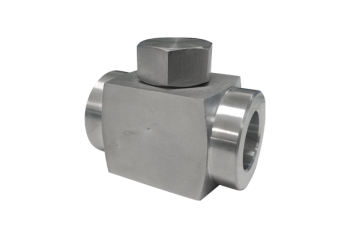

Forged Steel Check valve

Cast Steel – Internal Hinge

OD Type

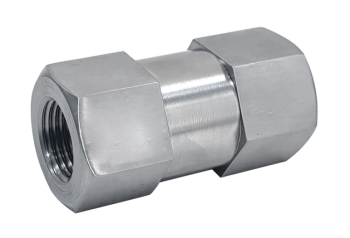

Spring Load Type – F X F

Spring Load Type – M X F

Cast Steel – Swing Type

We are offering a wide range of Check Valves that is generally used in flow metering applications, especially when a constant, calibrated, low flow rate must be maintained for some time, such as the idle fuel flow in a carburetor. Our check valves are appreciated in the market for low operating torque and high tensile strength. Further, these are provided in proper packaging to the clients in order to prevent wear and tear during transportation.

Application

- Chemicals industry

- Fats and fertilizer industry

- Shipbuilding

- Construction industry

Key Features

- Check valves are used for controlling flow in one direction only. Check valves should never be used as code safety relief devices

- Lowest Pressure Drop

- Easy to Install

- Alleviates Water Hammer

- End connections available in NPT; BSPT; Tube size; BSPP

- 100% valves are factory tested prior to dispatch.

- Pressure range from 1,000 to 10,000 psi.

Whenever the requirement arises for the fluid to be flowing in one direction only the check valves are used and these valves allow the fluids to flow in the forward direction only. They are also known as the two-port valves as they utilize one port for the entry of the fluids and another port for the fluid exit.

These check valves are also known as the non-return valve or the one-way valves or the clack valves or the retention valves.

Pattern : Straight

Design : Single Pc Design & 2 Pc Design

Rating : Up to 10,000psi

Connections : BSP & NPT, BSPT & Other Thread on Request

Standard : Metal to Metal & Soft Seat (Optional)

Soft Set : ‘O’ ring Viton

Size : 1/4” & 2”

Body Stock : Bar Stock & Forged Steel

Material : SS, CS and Other Material & Other as per your Requirements.